Sorry. We did not find anything.

September 10, 2024

MFTBC to build pilot facility for recovering materials from EV batteries

- MFTBC to partner with True 2 Materials Pte. Ltd. (T2M) on pilot facility for recovering anode, cathode and electrolyte materials from EV batteries

- Facility at Kawasaki Plant to test effectiveness of the T2M Total Material Recovery Process (TMR) with aim of commercialization

- Aims to maximize value of battery materials, reduce total costs of EVs and environmental impact to make customers’ transition to EV easier

Mitsubishi Fuso Truck and Bus Corporation (Headquarters: Kawasaki City, Kanagawa Prefecture, President and CEO: Karl Deppen, hereafter “MFTBC”) will build a test facility for recovering materials from used electric vehicle (EV) batteries at its Kawasaki Plant, in partnership with True 2 Materials Pte. Ltd (Headquarters: Singapore, CEO: Richard Carlow, hereafter: T2M). Starting in 2025, the companies will use the pilot plant to evaluate the reusability of anode, cathode, and electrolyte materials by battery cell makers.

The number of used EV batteries is expected to increase as demand for EVs expands amid global trends towards decarbonization. Used EV batteries can be reused for other purposes as they are, or they can be recycled to procure raw materials and components for other products. Through the tests jointly with T2M, MFTBC will consider a business venture that recycles used batteries from EV trucks, such as its electric light-duty eCanter, and EV passenger cars, into compounds that can be directly used as high-quality blended materials in battery cells.

MFTBC will first consider commercialization in Japan and investigate the possibility of overseas expansion in the future. While batteries account for a significant part of an EV’s cost, MFTBC intends to maximize the value of battery materials by developing effective retreatment processes, and thereby reducing the total cost of EVs. The company aims to eventually create an environment where customers can easily transition to e-mobility options.

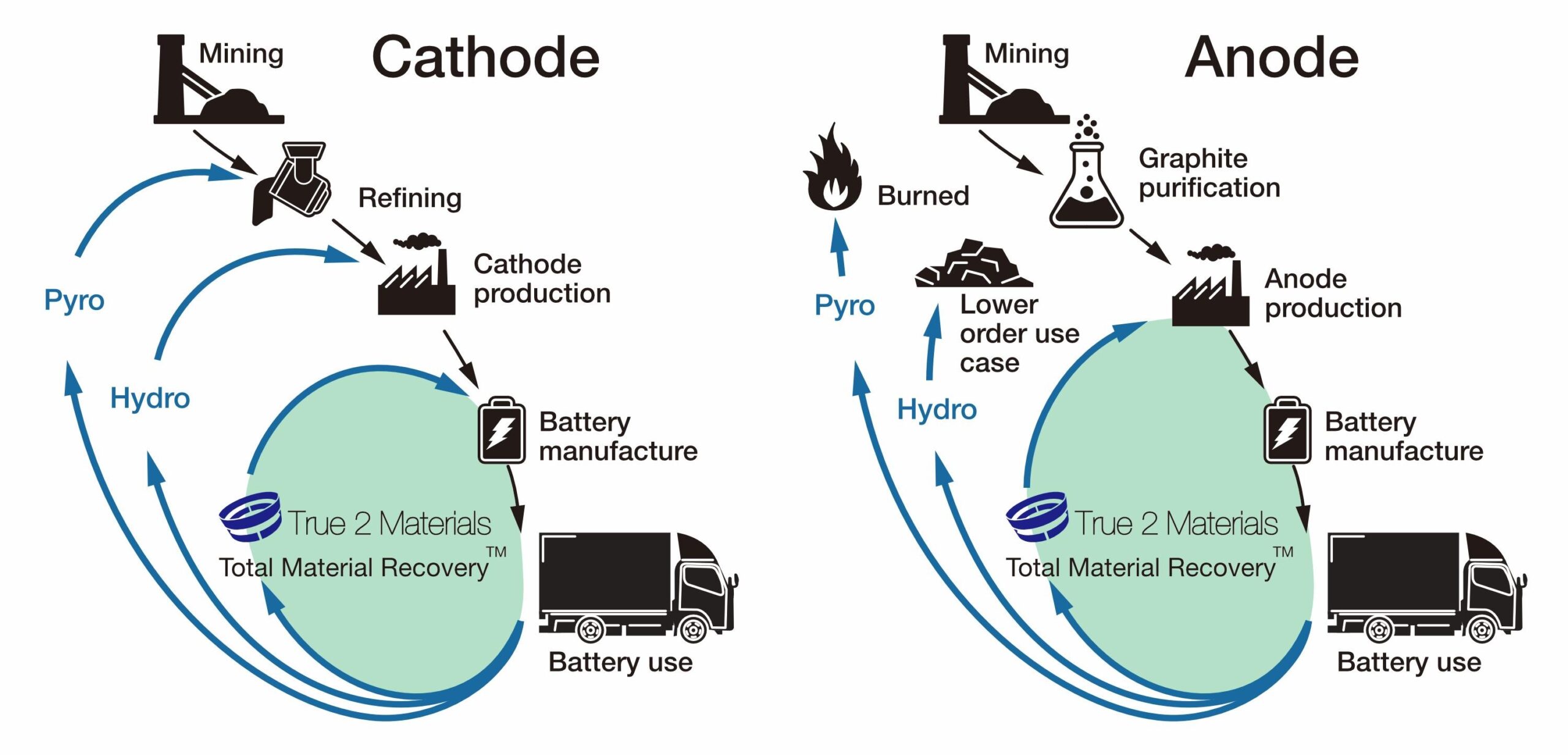

T2M has developed Total Material Recovery (TMR), a technology for processing used and scrap batteries into usable anodes and cathodes while minimizing loss of raw materials and their value and reducing environmental impact. The TMR process uses nano-level molecular techniques and is different from conventional pyrometallurgy and hydrometallurgy battery recycling. The technology allows recovery of up to 99.9% of all EV battery resources, a higher percentage than conventional methods, thereby maximizing battery resource value. This novel process also greatly reduces the amount of CO2 and other emissions, reducing the environmental impact of disassembly processing. In addition, it is expected that the cost of metal processing, which generally accounts for nearly 75% of the cost of the entire recycling process, will be significantly reduced.

This initiative is part of MFTBC’s FUSO eMobility Solutions framework to support customers’ EV shift. MFTBC will continue to develop products and services that contribute to realizing carbon neutrality by 2050.

Cycles of anode and cathode components for EV batteries

MFTBC at a Glance

Based in Kawasaki, Japan, Mitsubishi Fuso Truck and Bus Corporation (MFTBC) is one of Asia’s leading commercial vehicle manufacturers, with 89.29% of its shares owned by Daimler Truck AG and 10.71% by various Mitsubishi group companies. An icon in the Japanese commercial vehicle industry with a longstanding history of over 90 years with its FUSO brand, MFTBC manufactures a range of commercial vehicles including light, medium, and heavy-duty trucks and buses, and industrial engines for approximately 170 markets worldwide. In 2017, MFTBC introduced the eCanter, the first all-electric light-duty truck in series-production and in 2019, the Super Great – Japan’s first heavy-duty truck fitted with Level 2 Automated Driving Support Technology, a benchmark in the Japanese commercial vehicle market. MFTBC operates under the umbrella of Daimler Truck Asia, together with its partner organization Daimler India Commercial Vehicles (DICV) in India. This strategic unit allows the entities to collaborate on areas such as product development, parts sourcing and production to provide the best value to customers.

About the eCanter

The eCanter is the Japanese market’s first series-produced, all-electric truck (battery EV truck) introduced by MFTBC in 2017 With zero greenhouse gas emissions, it contributes to CO2 reduction, a major global issue. The eCanter is suited to inner-city routes as well as operations during late night and early morning hours, due to lower noise and vibration levels unique to EV trucks. The fully remodeled new eCanter launched in March 2023 caters to more diverse business needs with expanded chassis selections, body applications and cruising ranges. In addition to existing markets including Japan, 31 countries and regions in Europe and Oceania, MFTBC is expanding available overseas markets of eCanter including Asian markets such as Indonesia and Taiwan, Middle East and South America.

About “FUSO eMobility Solutions”

“FUSO eMobility Solutions” is a service portfolio offered in Japan to provide customers comprehensive support for introduction and operation of MFTBC’s EV trucks. It assists customers’ journey for carbon neutrality including their businesses, by covering all necessary elements for introducing and operating EV trucks such as the vehicle itself, consulting of operating and charging vehicles and supporting service for decarbonization of customer’s entire business portfolio.