Sorry. We did not find anything.

August 21, 2024

MFTBC improves inbound parts logistics management with digitization

- “Supply Chain Control Tower” project promotes digital transformation (DX) in manufacturing parts supply chain

- Project aims to enhance operational efficiency, optimize logistics costs, and improve stability in vehicle production processes

- Optimizes parts ordering operations, enables real-time monitoring of import parts transportation, captures arrival schedule at ports in Japan and predicts arrival time at plants

Mitsubishi Fuso Truck and Bus Corporation (Headquarters: Kawasaki City, Kanagawa Prefecture, President and CEO: Karl Deppen, hereafter: MFTBC) has launched a “Supply Chain Control Tower” project (hereafter: “the Project”) to improve efficiency in inbound parts logistics management through digital transformation.

The company aims to automate processes in addition to monitoring vessels carrying parts — and estimating their arrival times at factories in Japan — in real time. The newly setup functions replace monitoring tasks conducted by logistics operators, leading to significant reductions in working time and cost.

Background and goals of the Project

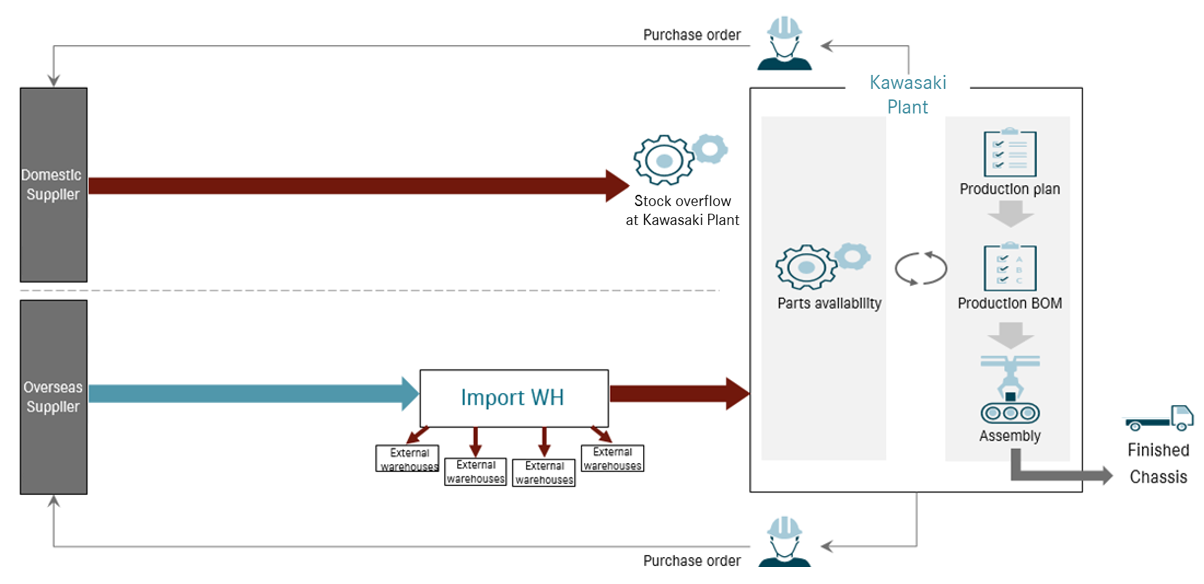

One single truck or bus is assembled with more 10,000 parts. Manufacturing parts are delivered daily from hundreds of domestic and overseas suppliers to MFTBC’s production sites. Parts ordering and transportation are organized at weekly and monthly intervals, based on multiple factors, such as the production capacity of assembly lines and parts inventory at logistics warehouses. Daily monitoring and management of inbound manufacturing parts are currently performed by logistics operators.

Under the Project, MFTBC aspires to maximize work efficiency with DX throughout the entire cycle of inbound parts logistics, from ordering vehicle parts to checking inventory, production planning and the manufacturing of vehicles.

The commercial vehicle industry has seen recent supply chain disruptions due to factors including COVID-19 and a semiconductor shortage. This project is expected to improve stability in the logistics and production systems by responding more agilely to disruptions.

The “IBL*1 Control Tower”*2, a system that MFTBC has been using since 2023 to digitally optimize manufacturing parts transportation by domestic suppliers, is part of the Project.

Employing real-time tracking, “IBL Control Tower” predicts the arrival time of vehicles based on location data and road traffic information for vehicles transporting parts from domestic suppliers to MFTBC factories.

*1 IBL: Inbound Logistics

*2 Please refer to MFTBC’s press release on December 26, 2022.

[Image of inbound parts logistics]

Optimization of parts ordering operations

To improve the efficiency of logistics operations, MFTBC has optimized parts ordering systems by introducing automated monitoring and adjusting other processes.

Manufacturing parts are usually ordered at defined intervals, depending on suppliers’ locations. Previously, operators needed to manually calculate and input order amounts based on production line status, available inventory, and production plans. Newly introduced software enables inventory monitoring through automated cross-checking of vehicle production schedules and parts ordering plans.

The inhouse-developed system automates all parts ordering, calculation and input operations, which has led to an expansion of monitoring scope. This bolstering of system capacity will lead to reducing excess inventory and cutting parts storage costs.

Real-time monitoring of transport status and estimated time of arrival of import parts at Japanese ports

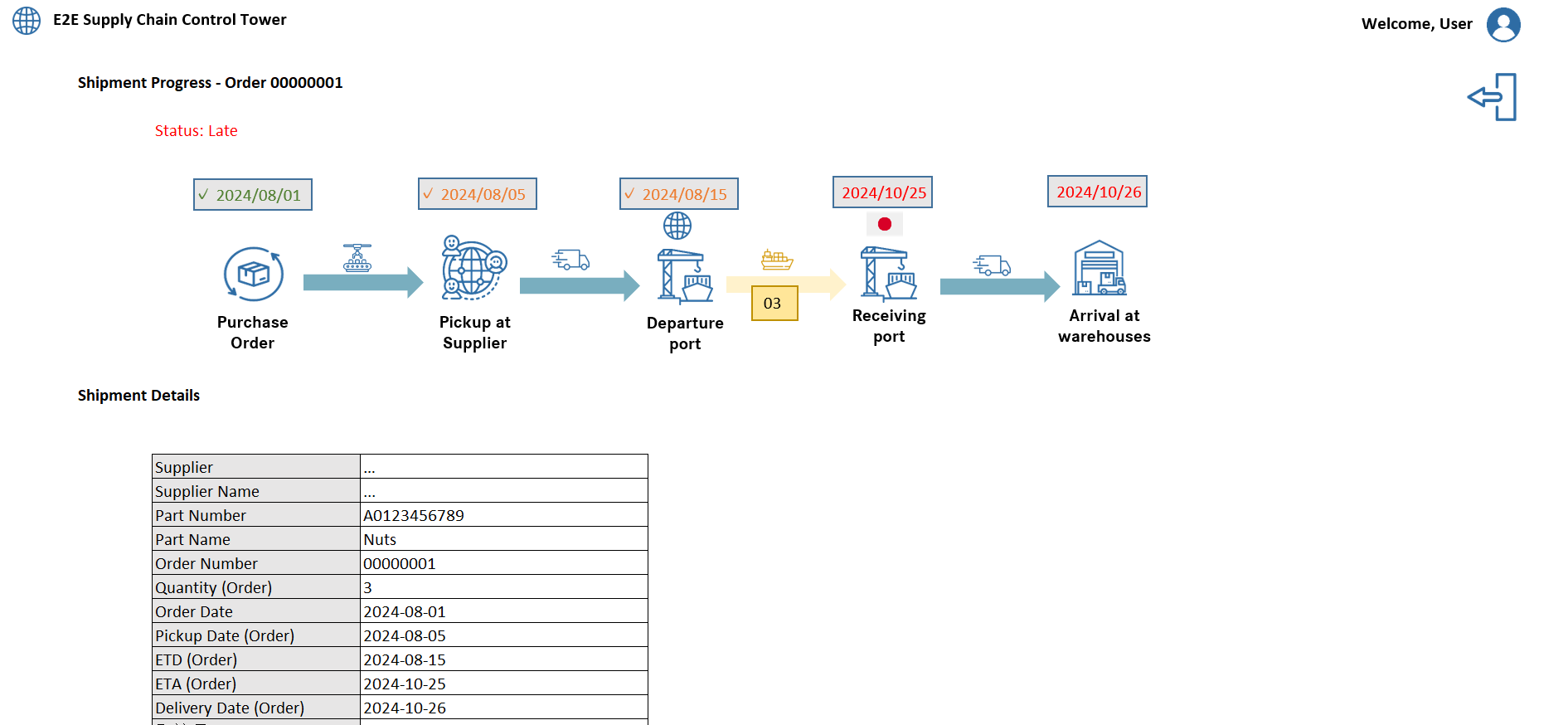

MFTBC has made it possible to monitor the transport status and estimated arrival time of imported manufacturing parts from overseas to ports in Japan.

Imported parts are usually shipped by vessels. Cruising and arrival schedules of shipping vessels can change, due to traffic or customs procedures as well as weather conditions.

Accurate and timely monitoring of shipping vessels and reflecting the data in production plans and parts ordering are essential for streamlining processes. Conventionally at MFTBC, operators checked the status of shipping vessels by methods such as browsing the websites of vessel owners or via email.

Under the Project, however, MFTBC’s inhouse-developed system utilizes API services*3 to centrally monitor the real-time shipping status and estimated arrival time of all vessels. This helps operators to reduce daily work time and MFTBC to reduce outsourcing costs.

*3 API: Application Programming Interface. A system that integrates different software and applications to make them accessible from a single platform.

[Screen image of real-time monitoring of import parts transportation]

Under the Project, MFTBC will continue its DX efforts throughout the entire logistics process, in order to maximize the work efficiency of parts delivery management and establish more stability in vehicle production by identifying and mitigating against risks from external factors with shorter lead times and enhanced precision.

MFTBC at a Glance

Mitsubishi Fuso Truck and Bus Corporation (MFTBC) is a commercial vehicle manufacturer based in Kawasaki City, Japan. 89.29% of its shares are owned by Daimler Truck AG and 10.71% by various Mitsubishi group companies. MFTBC provides trucks, buses and industrial engines under the FUSO brand with a longstanding history of over 90 years, serving approximately 170 markets worldwide. MFTBC proactively develops cutting-edge technologies such as electrification , with its eCanter being Japan’s first mass-produced electric light-duty truck. MFTBC’s heavy-duty Super Great Truck was also the first of its kind in Japan to include SAE Level 2-equivalent automated driving support technology, now a benchmark in the Japanese commercial vehicle market.